The Myth: Preservation of parts or assets is expensive

Fact: In reality, the whole affair is affordable and better still, it creates long-term savings.

From the outset, when people discuss corrosion protection and preservation, it seems like an expensive process especially when you go for a comprehensive system.

Corrosion can lead to costly returns and quality issues on precision components. In regards to larger assets, an asset preservation program can be designed to help reduce loss of downtime due to corrosion and other costs associated with this issue. Protection of equipment during storage will not only help in reducing costs but also makes it easier for reinstating the equipment when needed.

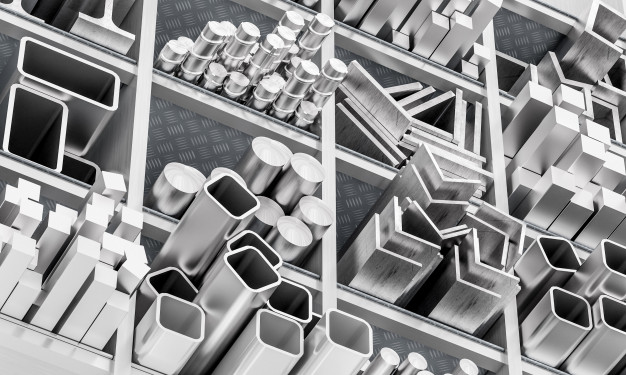

The Myth: Aluminium does not corrode

Fact: Aluminium can corrode, but it cannot rust.

Both rusting and corrosion are forms of oxidation-related stress that occur in metals. The difference is that rusting only occur in iron — as well as iron alloys like steel — whereas corrosion can strike any metal or alloy.

Aluminium does not contain iron, so it cannot rust. It can still corrode if not properly maintained, but aluminium is naturally protected against rusting because it lacks any iron.

The Myth: If I use corrosion resistant material then there is no need for corrosion protection.

Fact: Any metal can rust or oxidise in the right environment, with the exception of gold

Gold never reacts with oxygen, which means it will not rust or tarnish. Adding a maintenance protocol and using corrosion preventative products will prolong the life expectancy of metal parts and most of all the assets these are built up of.

The Myth: Cleaning parts will reduce corrosion

Fact: Cleaning parts can actually give corrosion the perfect environment to start again or to initiate.

A clean metal surface especially if machined is more susceptible to corrosion. Once parts are cleaned they must have a corrosion preventative or packaged using the right products to ensure they reach their intended destination corrosion free and fit for purpose.

The Myth: Nitrogen purging is a far better way of protecting sealed vessels against corrosion than VpCI Technology

Fact: Not only is Nitrogen purging far more expensive to applicate and monitor the health and safety implications in doing so are huge.

A vessel purged with Nitrogen will cause asphyxiation within seconds if it is entered without adequate protection, or if the exhaust gas from the vessel is inhaled. The immediate reaction is marked by struggling for breath, and unconsciousness follows in a few seconds if the worker is not removed.

VpCI Technology is a much safer and cheaper alternative that has been proven to be more effective against corrosion compared to nitrogen purge.

The Myth: Corrosion inhibitors only work in a single phase.

Fact: VpCl technology provides corrosion protection in multiple phases.

Cortec® VpCl technology provides corrosion protection in interface, liquid phase, and vapour phase. Unlike conventional corrosion inhibition methods, Cortec® VpCl’s are self-replenishing.

Get in touch – it would be great to hear any misconceptions you have come across or even any conceptions you may have and would like clarification on.